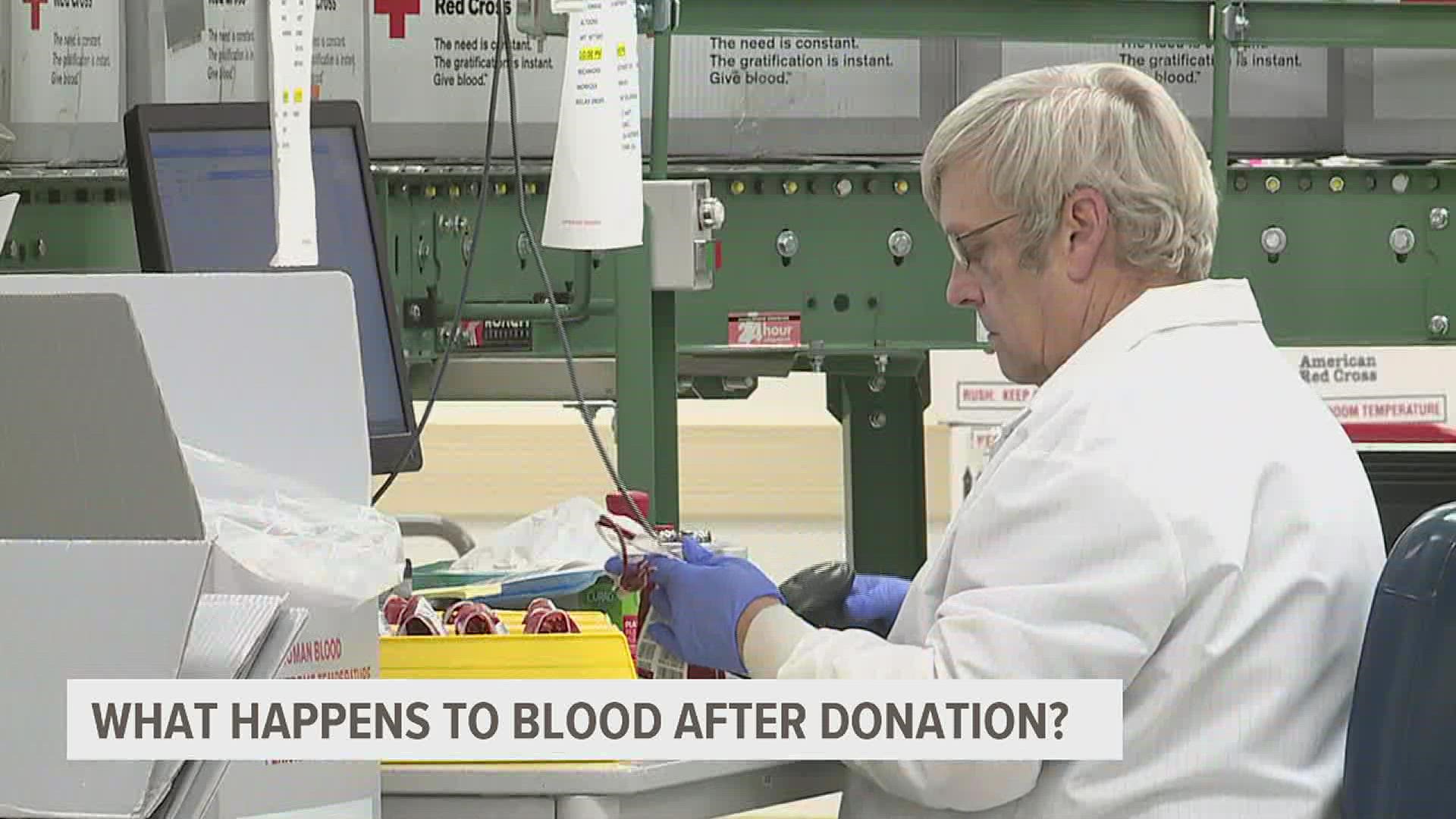

PENNSYLVANIA, USA — Located in Richland Township, Pennsylvania is a 131,000-square-foot American Red Cross blood processing facility, where a team of employees work to turn donated blood into life-saving products

According to the Red Cross, in modern medical treatments, patients may receive a pint of whole blood or just the specific components. This facility is where they separate blood into those components.

“To my experience, very few people understand what exactly that entails,” said Director of Manufacturing Bob Davis.

At the facility, whole blood is spun in refrigerated centrifuges to separate from the plasma and red cells.

Platelets are kept in a machine that constantly moves back and forth to prevent them from clotting.

“If we let it just sit and settle in a bag, it’s going to clot and clump in the bag,” said Davis.

Testing is done at a different facility.

After the blood is processed, it’s ready to be shipped. While this facility primarily serves hospitals in Western Pennsylvania, West Virginia, Virginia and parts of Ohio, some of the rare blood can be sent around the world.

“We actually, in our region, have quite a few rare donors that we’ve shipped to Hawaii, Canada, [or] to other countries,” said Immunohematology Reference Lab Supervisor Angela Day.

From the collection, to processing, to ready-to-ship the process takes about 24 hours. It’s important work that Davis and his team are more than happy to do.

“That life-saving mission we’re all on is what, at the end of the day, really drives us to continue the high-quality work that we perform,” said Davis.

On an average day, the plant can make 800 blood products.